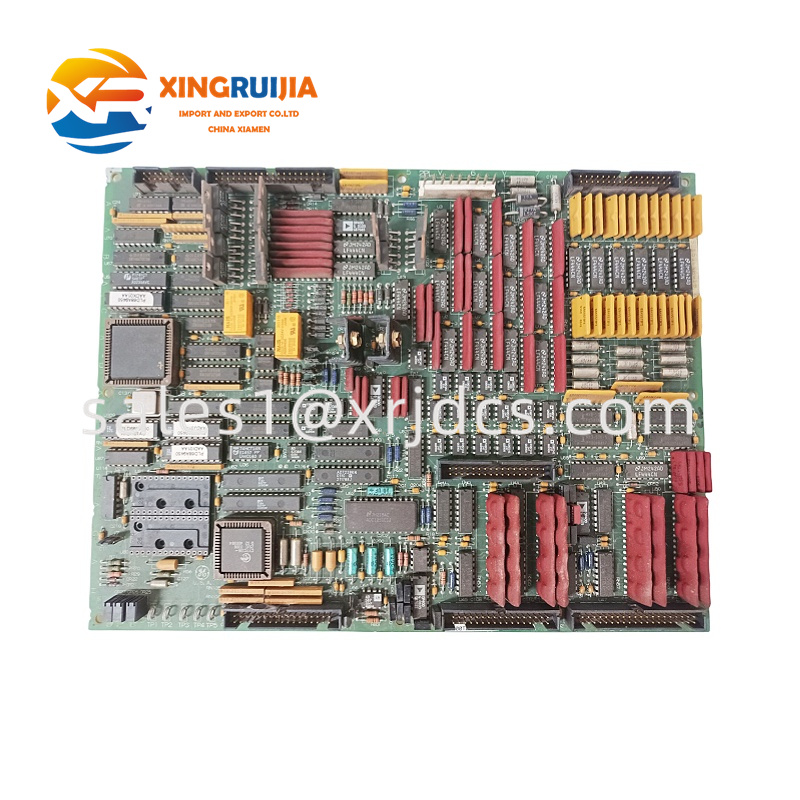

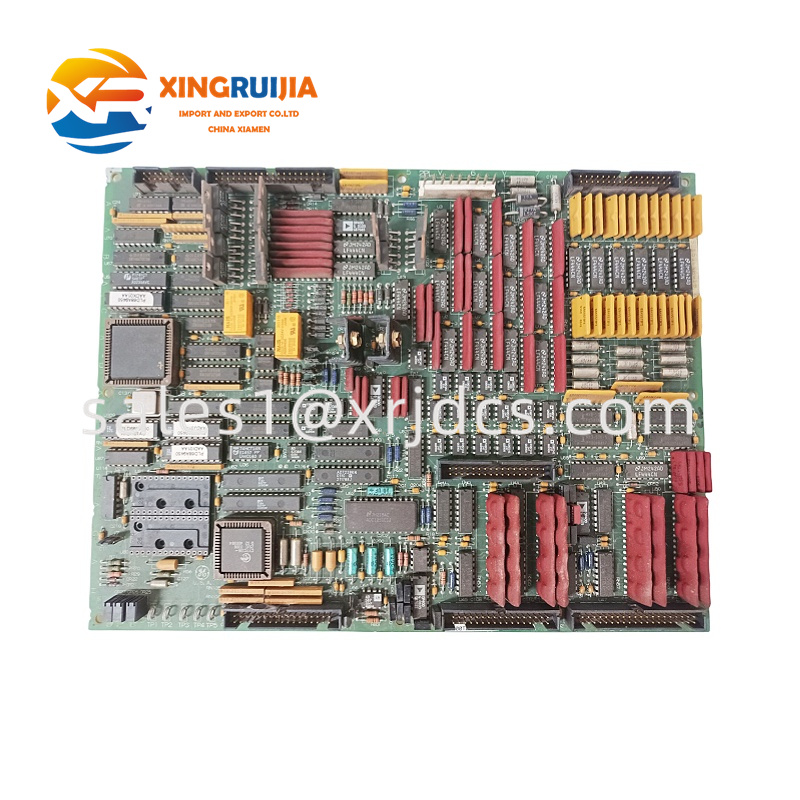

GE DS215TCQAG1BZZ01A Control I/O Terminal Board

The GE DS215TCQAG1BZZ01A is a highly specialized I/O terminal board designed explicitly for the Mark VIe turbine control system. This board serves as a critical interface, managing the connection between the turbine's sensors, actuators, and the central controller.

·Manager: Jinny

·E-mail:sales1@xrjdcs.com

·Tel: + 86-15359273791 (WhatsApp)

·Wechat: + 86-15359273791

Product Description

GE DS215TCQAG1BZZ01A: Mark VIe Turbine Control I/O Terminal Board

The GE DS215TCQAG1BZZ01A is a highly specialized I/O terminal board designed explicitly for the Mark VIe turbine control system. This board serves as a critical interface, managing the connection between the turbine's sensors, actuators, and the central controller. It is engineered for extreme reliability in demanding environments like power generation, ensuring precise data acquisition and control signal output for the safe and efficient operation of gas or steam turbines.

Technical Parameters

Manufacturer: GE Energy (General Electric)

System Compatibility: Mark VIe Turbine Control System

Board Type: I/O Terminal Board

Function: Analog and Digital Signal Interface

Part Number Specifics: The suffix 'BZZ01A' indicates a specific factory configuration for analog input/output and digital I/O functionality.

Manufacturer: GE Energy (General Electric)

System Compatibility: Mark VIe Turbine Control System

Board Type: I/O Terminal Board

Function: Analog and Digital Signal Interface

Part Number Specifics: The suffix 'BZZ01A' indicates a specific factory configuration for analog input/output and digital I/O functionality.

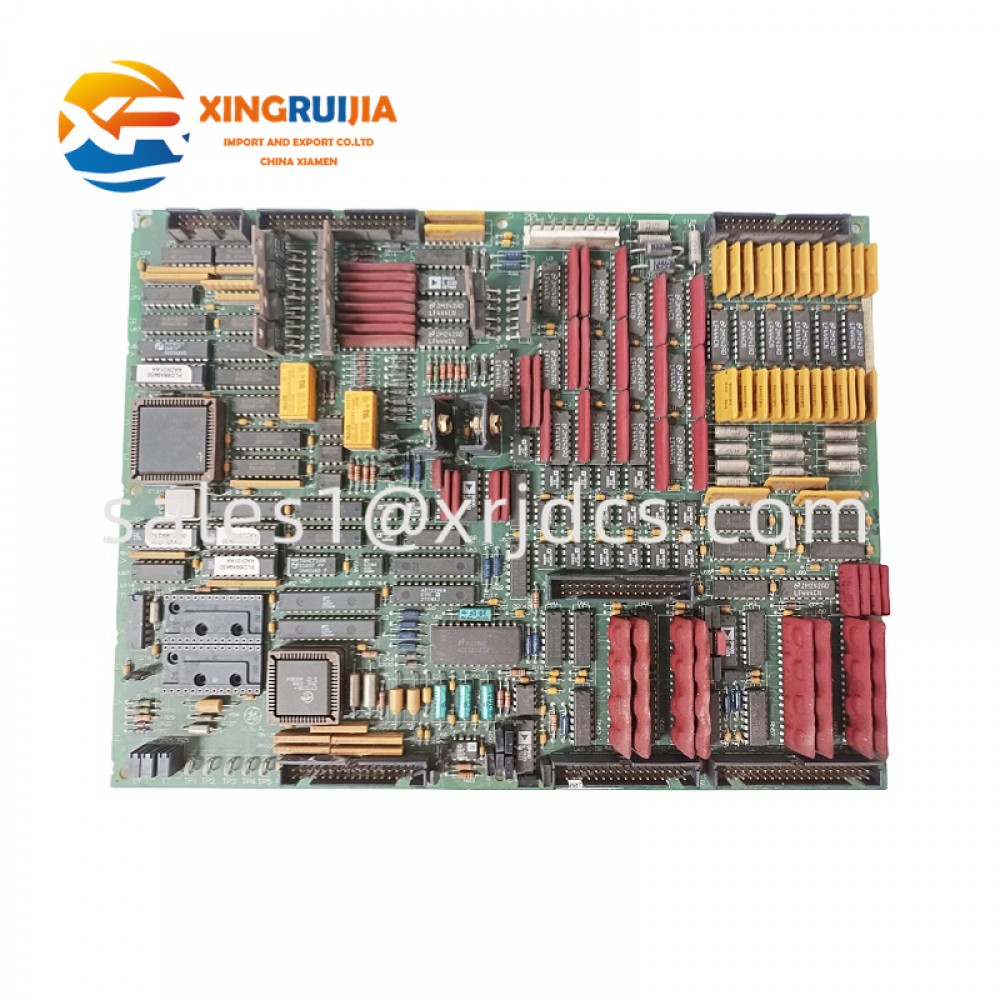

Key Characteristics & Design

This terminal board is built with features essential for critical turbine control:

Robust Signal Conditioning: Provides isolation and filtering for analog signals, protecting the control system from electrical noise and transients.

High-Density Connection: Features multiple channels for connecting various field devices, including thermocouples, RTDs, analog inputs/outputs, and digital signals.

Redundancy Support: Designed to integrate into redundant control architectures, enhancing system availability and fault tolerance.

Rugged Construction: Built to withstand the high temperatures and vibrations typical of turbine environments.

Plug-in Design: Facilitates easy installation and replacement within the Mark VIe rack assembly.

Application and Use

The primary application of the DS215TCQAG1BZZ01A is within the GE Mark VIe speedtronic control system, which is used for:

Gas Turbine Control and Sequencing

Steam Turbine Control

Integrated Combined Cycle Power Plant Control

Generator Excitation and Protection

It acts as a local interface point, gathering critical operational data (e.g., temperature, pressure, vibration) and executing control commands from the main processor.

.jpg)

Structure and Installation Overview

The board is a printed circuit assembly (PCA) that slides into a designated slot in the Mark VIe controller rack. It connects to the system backplane for communication with the control processor and to field devices via its front-facing terminal blocks. Installation and removal must be performed by qualified personnel with all power disconnected. Configuration is typically handled through the Mark VIe toolset software.

Maintenance Guidelines

Maintenance primarily involves periodic inspection for signs of physical damage or contamination. For troubleshooting, the Mark VIe system diagnostics can pinpoint faults to the module level. Replacement should be carried out with an identical, factory-configured part number. Always ensure a static-safe environment when handling the board and follow strict lockout/tagout procedures.

——————————————————————————————————————

·Manager: Jinny ·E-mail: sales1@xrjdcs.com

·Tel: + 86-15359273791(WhatsApp) ·Wechat: + 86-15359273791

The GE DS215TCQAG1BZZ01A is a highly specialized I/O terminal board designed explicitly for the Mark VIe turbine control system. This board serves as a critical interface, managing the connection between the turbine's sensors, actuators, and the central controller.

·Manager: Jinny

·E-mail:sales1@xrjdcs.com

·Tel: + 86-15359273791 (WhatsApp)

·Wechat: + 86-15359273791

-270x270.jpg)